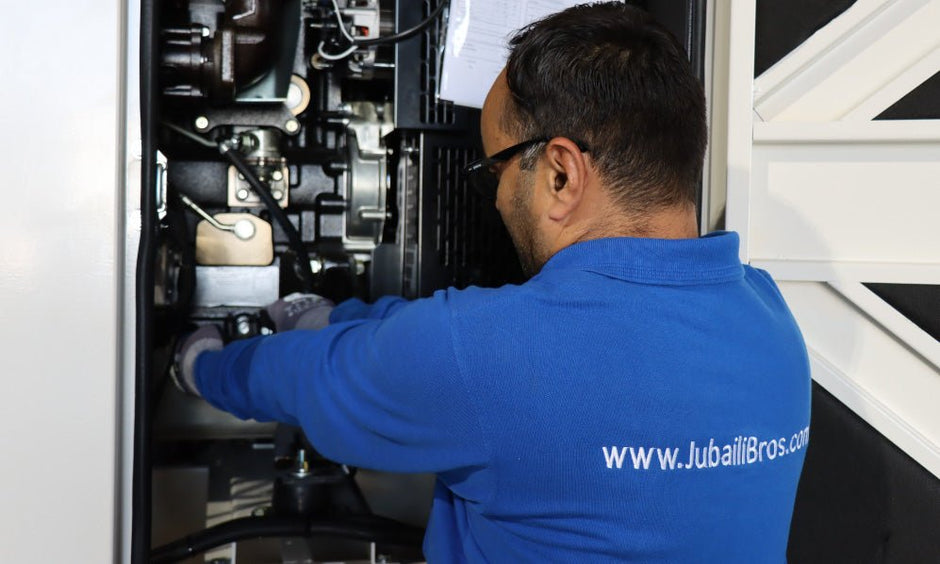

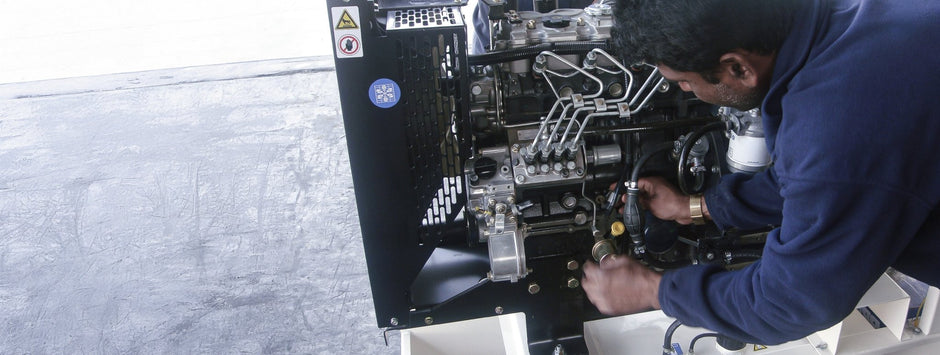

Visible exhaust smoke from a diesel generator is more than a cosmetic issue—it indicates incomplete combustion, wasted fuel, and potential engine damage. The smoke’s color—black, white, or blue—provides valuable clues to the underlying problem. This guide outlines common causes, diagnostic checks, and corrective actions, based on the field experience of Jubaili Bros service engineers.

Black Smoke (Soot)

Root cause: Excess fuel or insufficient air supply.

Common Causes and Solutions

-

Over-fueling or low-load wet-stacking

• Symptom: Black haze during low-load operation

• Fix: Run generator at ≥ 60% load for at least 30 minutes or use a load bank monthly to burn off carbon deposits -

Restricted air filter

• Symptom: Restriction gauge in red; vacuum > 625 mmH2O

• Fix: Replace filter element and check pre-cleaner and intake ducts -

Turbocharger under-boost

• Symptom: Low manifold pressure, audible air leaks

• Fix: Tighten clamps, replace torn intercooler boots, test waste-gate actuator -

Faulty injectors

• Symptom: Uneven exhaust manifold temperatures, high fuel return

• Fix: Remove and pop-test injectors; replace worn nozzles -

Incorrect injection timing

• Symptom: Engine recently serviced; timing misaligned

• Fix: Recalibrate timing using dial indicator or ECU software

White Smoke (Unburned Fuel or Coolant)

Root cause: Fuel failing to ignite, or coolant entering the combustion chamber.

Cold-Start White Smoke

-

Low cylinder temperature

• Fix: Check block heater, glow plugs, or intake heater operation -

Low compression

• Fix: Perform leak-down test and inspect piston rings or valves

Persistent White Smoke After Warm-Up

-

Injector dribble

• Fix: Replace injector set -

Coolant ingress

• Symptom: Sweet-smelling exhaust, rising coolant level

• Fix: Pressure-test cooling system, borescope cylinders, replace gasket or liner O-rings

Blue Smoke (Oil Burning)

Root cause: Engine oil entering the combustion or exhaust stream.

Common Sources and Remedies

-

Worn valve-stem seals

• Symptom: Blue smoke on deceleration

• Fix: Replace seals and inspect valve guides -

Piston ring wear or glazing

• Symptom: Excessive crankcase blow-by, high oil consumption

• Fix: Compression test, hone cylinders, install new rings -

Turbo oil seal leak

• Symptom: Oil in charge-air cooler, oily turbine housing

• Fix: Rebuild turbo, check crankcase pressure relief -

Overfilled crankcase

• Fix: Drain to full mark; check for fuel dilution (Article 30)

Diagnostic Flowchart

Step 1: Observe smoke color ➔ Step 2: Refer to matching section ➔ Step 3: Check simple items (filter, oil level) ➔ Step 4: Measure boost and exhaust temperature ➔ Step 5: Inspect injectors ➔ Step 6: Perform compression or leak-down test ➔ Step 7: Turbo inspection ➔ Step 8: Engine teardown if needed.

Tools and Instruments

- Exhaust opacity meter (target Ringelmann ≤ 1 at full load)

- Boost gauge for intake pressure verification

- Infrared thermometer for exhaust runner temperature comparison (ΔT < 40 °C)

- Oil consumption measurement kit

Preventive Measures

- Replace air filters when pressure drop exceeds 3 kPa

- Perform full-load generator runs monthly to avoid carbon buildup

- Use low-ash API CK-4 15W-40 oil to limit deposit formation

- Monitor injector balance and fuel quality during regular service (Article 31)

- Install crankcase breather filters to manage blow-by pressure

Conclusion

Exhaust smoke color is one of the most valuable early indicators of generator health. By interpreting its characteristics and applying the recommended steps, operators can prevent costly engine damage and maintain peak performance.

Need expert support? Contact Jubaili Bros—our mobile service units are equipped with smoke meters, injector test kits, and turbo diagnostic tools for on-site resolution.