Two environmental factors quietly erode generator performance long before the engine wears out or fuel degrades: high ambient temperature and elevation above sea level. Both reduce air density, which in turn limits the oxygen available for combustion. Less oxygen means lower fuel delivery, reduced engine output, hotter alternators, and shortened component life. Manufacturers provide derating curves to help consultants and installers account for these site-specific conditions and avoid underperformance. This article explains how to apply those curves and size your generator correctly for high-temperature and high-altitude sites.

Why Air Density Affects Power

Diesel engines operate within a fixed air-to-fuel ratio. When intake air becomes thinner—due to heat or altitude—the engine must reduce fuel delivery to avoid smoke, poor combustion, or emissions non-compliance. Air density drops approximately 1% per 100 m of altitude gain and 0.3% per °C of temperature rise. Sites in mountainous regions with high daytime temperatures face a compounded derating effect. Jubaili Bros' Sales Training 2025 module captures this succinctly: “Generators operating above 1 000 m require a 1% power reduction for every additional 100 m.”

Engine Derating Curve Overview

Each engine manufacturer provides derating curves. Below is a simplified table based on common Perkins values, combining temperature and altitude effects for typical operating conditions:

| Altitude (m) | 25 °C | 40 °C | 50 °C |

|---|---|---|---|

| Sea level | 100 % | 96 % | 92 % |

| 1 000 | 90 % | 86 % | 82 % |

| 2 000 | 80 % | 75 % | 70 % |

| 3 000 | 70 % | 64 % | 60 % |

Always apply the peak site conditions—typically the hottest midday temperature—rather than the 24-hour average. Oversizing based on worst-case conditions ensures long-term reliability.

Alternator Derating Considerations

Alternators are rated to operate within thermal rise limits specified by ISO and ANSI standards. According to Jubaili Bros’ technical training, derating begins when ventilation air exceeds 40 °C. Leroy-Somer guidelines recommend reducing kVA output by 3% for every 10 °C above 40 °C, and 0.4% per 100 m above 1 000 m. Whichever derate—engine or alternator—is more severe becomes the sizing limit. For hot climates or high-altitude installations, always check both ratings independently.

Cooling System Impact

High ambient temperatures demand more from the radiator and fan assembly. Fan horsepower can increase by 15–25% to maintain airflow, and a standard radiator may no longer be sufficient. This is why tropical-rated radiator packs are often required. Jubaili Bros cautions that undersized radiators lead to persistent high coolant temperature alarms, premature shutdowns, and reduced equipment life.

Worked Example: Applying Derating

Consider a mining camp at 1 800 m elevation and 45 °C ambient temperature, requiring 800 kW of continuous power.

- Altitude derate: 8 × 1% = 8% → 92% base

- Temperature derate: 20 °C above 25 °C × 0.3% = 6% → 92% × 94% = ~86.5%

Required set size = 800 kW / 0.865 ≈ 925 kW. A 1 000 kVA prime-rated generator (≈900 kW) would safely meet this requirement while retaining some headroom for motor-start transients.

Additional Environmental Impacts

Beyond engine and alternator derating, high-altitude or high-temperature sites introduce several knock-on effects:

- Fuel volatility: Lower atmospheric pressure reduces diesel boiling point—vent lines must equalise properly.

- Battery derating: For every degree below 25 °C, battery cranking amps drop by ~0.8%—common in highland nights.

- Air filtration: Dust levels are often higher at elevation. Use dual-element heavy-duty air cleaners.

- Electronics: Generator controllers must be rated for extreme temperatures (e.g., –20 °C to +70 °C).

Derating Mitigation Strategies

- Oversize the set: The most direct solution—select a larger frame size to compensate for capacity loss.

- Charge-air aftercooling: Reducing intake air temperature by 20 °C can improve engine power by ~5%.

- Advanced turbocharging: Variable-geometry turbos maintain boost pressure at higher altitudes but increase cost and maintenance.

- Accelerated service schedule: Hot sites require more frequent coolant checks and annual radiator cap replacement.

Design Checklist for High-Altitude or High-Heat Sites

- Use meteorological data to obtain the 99% design temperature and elevation.

- Apply manufacturer derating curves to both engine and alternator outputs.

- Check transient response under derated power conditions.

- Select tropical-rated radiators or remote cooling packages if coolant temperature exceeds 95 °C.

- Ensure room ventilation flow handles increased heat rejection at lower air density.

- Document all derating factors and assumptions in the project specification for approval and O&M handover.

Conclusion

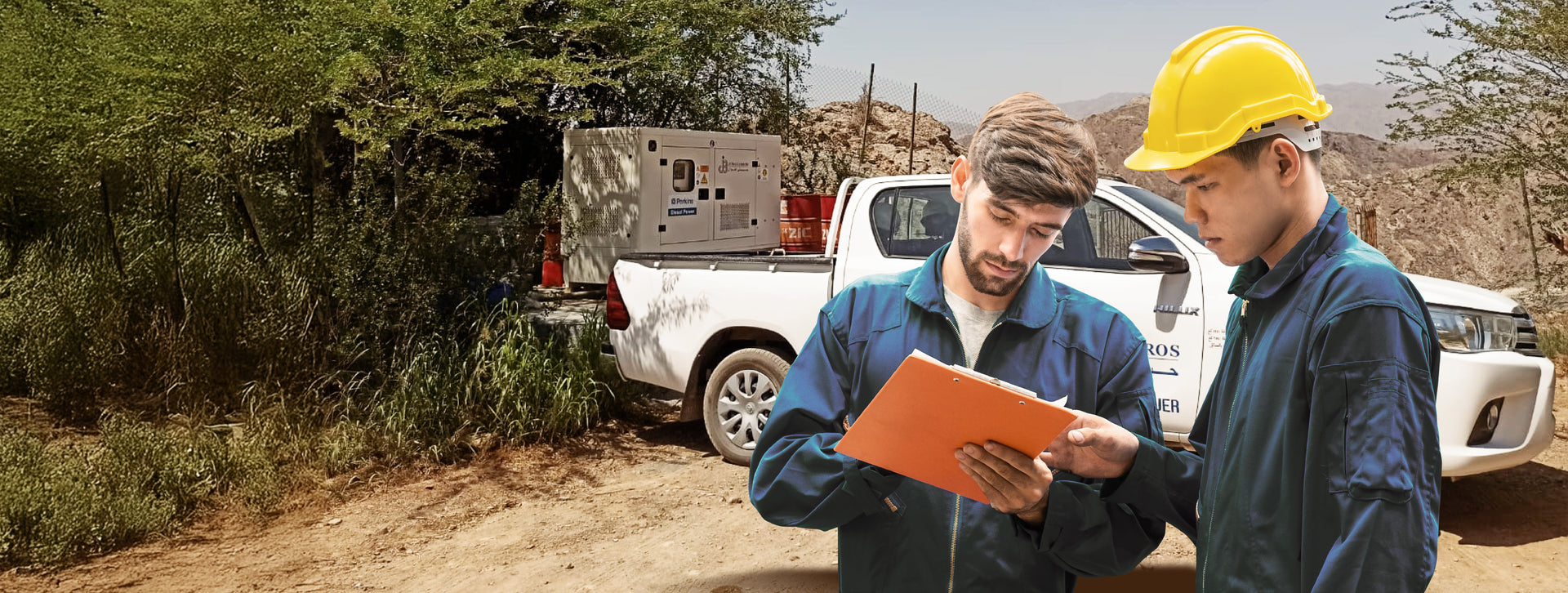

Altitude and ambient temperature are often overlooked in early design phases—but their effect on generator performance is significant. Proper derating and thermal management ensure your generator delivers its rated performance under real-world site conditions. With tools like derating curves, tropical radiator packs, and advanced air systems, Jubaili Bros helps clients deliver dependable power even in the toughest environments.

Have questions about derating or high-altitude installations? Contact Jubaili Bros for engineering support and tailored generator sizing.