Stricter air-quality regulations are now standard across major global markets, from the U.S. EPA Tier 4 Final rule to the EU Stage V directive. Facility owners and consultants who previously specified fuel-optimized (non-compliant) generators must now account for diesel particulate filters (DPF), selective catalytic reduction (SCR) systems, and electronic engine management when planning their power systems. This article explores why emissions compliance matters, explains the meaning of engine variant letters, and outlines how Jubaili Bros delivers turnkey generator sets that meet emissions standards without sacrificing reliability.

Why Emissions Compliance Is Important

Combustion engines emit pollutants that affect human health and the environment:

- Nitrogen oxides (NOx): Cause smog and contribute to respiratory issues.

- Particulate matter (PM): Penetrates deep into lung tissue, especially dangerous in urban areas.

- Carbon monoxide (CO): A toxic gas that can be fatal in enclosed spaces.

Regulators now cap these emissions, typically measured in grams per kilowatt-hour (g/kWh). Tier 4 Final and Stage V rules reduce particulate matter by up to 95% compared to pre-2000 standards and require the use of after-treatment technologies to meet these levels.

Understanding Engine Variant Letters

Engine suffix letters identify the emissions tier an engine complies with. For example, Perkins engines use letters A through E to indicate emission configuration:

| Suffix | Typical Market | Emissions Tier |

|---|---|---|

| A | Middle East, Africa | Fuel-optimized (non-compliant) |

| B / C | Latin America, parts of Asia | Tier 2 / Stage II |

| D | EU (pre-2021), GCC refineries | Stage III A / Tier 3 |

| E | U.S., EU, Japan | Tier 4 Final / Stage V |

Choosing the wrong variant in a regulated country can result in fines or rejected permits. Jubaili Bros’ application engineers help ensure the correct engine variant is specified for each project.

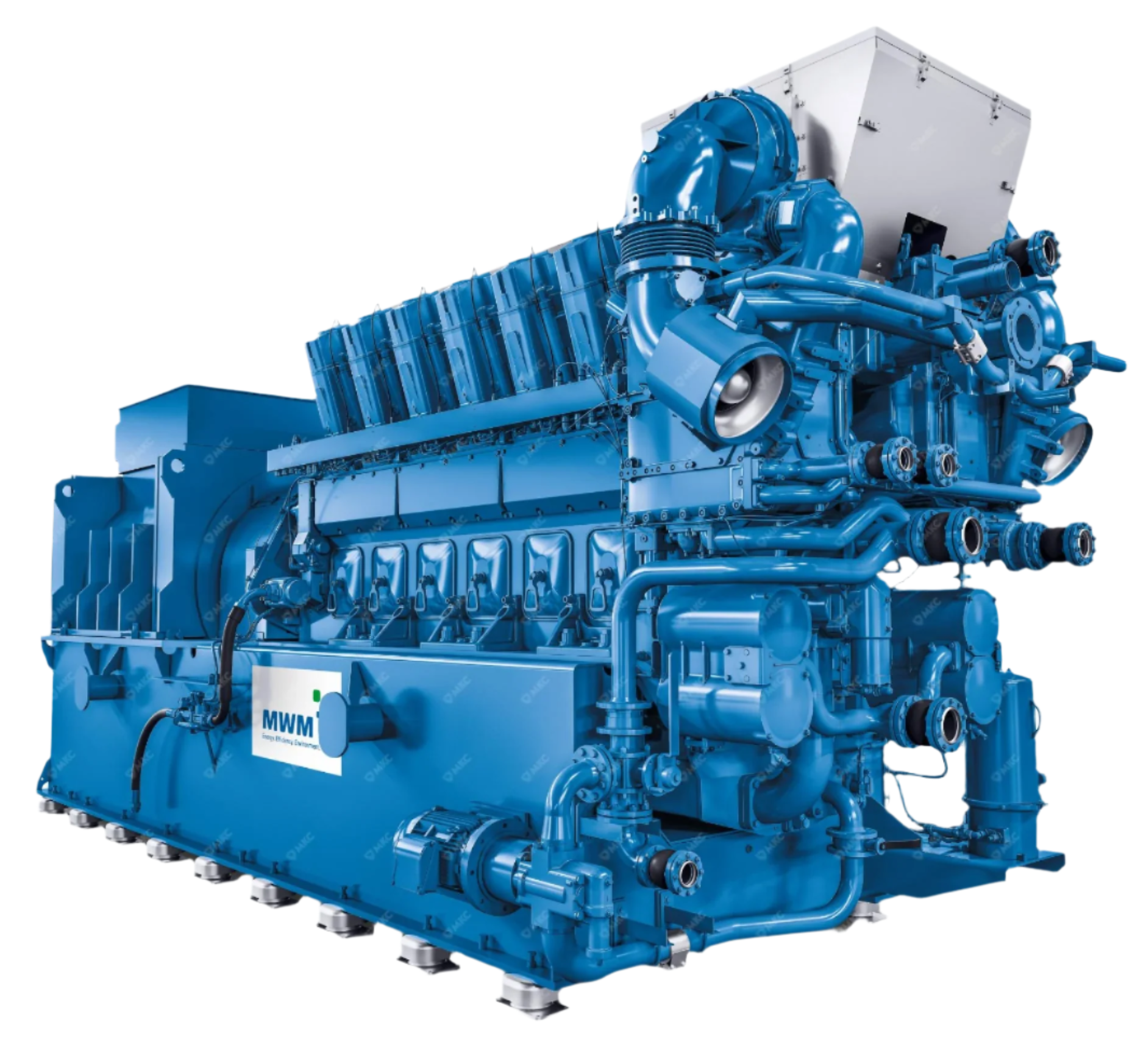

Key Technologies in Emission-Controlled Engines

- Electronic Control Module (ECM): The ECM manages fuel injection, boost pressure, and exhaust treatment based on real-time load and ambient conditions. It is essential for Tier 4 and Stage V compliance.

- Diesel Particulate Filter (DPF): Captures soot particles from the exhaust. Regeneration cycles burn off the accumulated soot, converting it into CO2.

- Selective Catalytic Reduction (SCR): Injects urea (AdBlue®) into the exhaust to convert NOx into nitrogen and water. SCR also improves fuel economy by allowing leaner engine operation.

- Exhaust Gas Recirculation (EGR): Reduces peak combustion temperatures by recirculating cooled exhaust gas into the intake stream, lowering NOx formation.

Impact on Generator Sizing and Load Performance

Adding after-treatment systems introduces backpressure and thermal inertia. Without compensation, this can reduce load acceptance or cause stalling under step load. Emissions-compliant sets typically include:

- Higher torque engines to recover from transients more quickly

- Electronic actuators (e.g., twin-bank Heinzmann systems) for precise fuel metering

- Controllers with fast-response load sharing and frequency control

Jubaili Bros generator packages are engineered to maintain transient response even with full emissions kits installed.

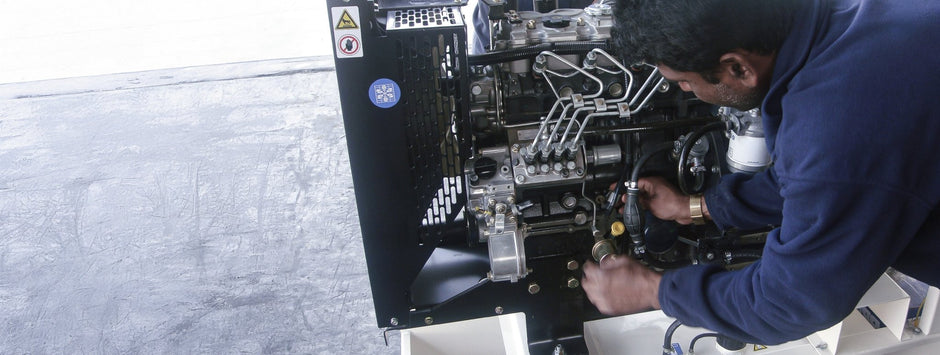

Maintenance Requirements for Emission Systems

- Urea handling: Use ISO 22241-compliant AdBlue stored between 5°C and 25°C. Avoid crystallization to prevent SCR nozzle blockage.

- DPF cleaning: While low-sulfur diesel reduces ash accumulation, periodic cleaning (every 4,000–6,000 hours) is still required.

- Sensor calibration: Temperature, pressure, and NOx sensors should be verified annually for accuracy.

- Firmware updates: ECM software may need periodic updates to match changes in fuel formulations or emissions strategies.

Evaluating Cost vs Benefit

Emissions-compliant generators cost more up-front—typically 20–30% higher than standard sets. However, they offer several advantages:

- Eligibility for LEED-certified, government-funded, or export projects

- Reduced risk of permitting delays and rework

- Lower fuel consumption (2–3%) from optimized combustion

Over a multi-year operating period, the total cost of ownership can be favorable compared to non-compliant alternatives.

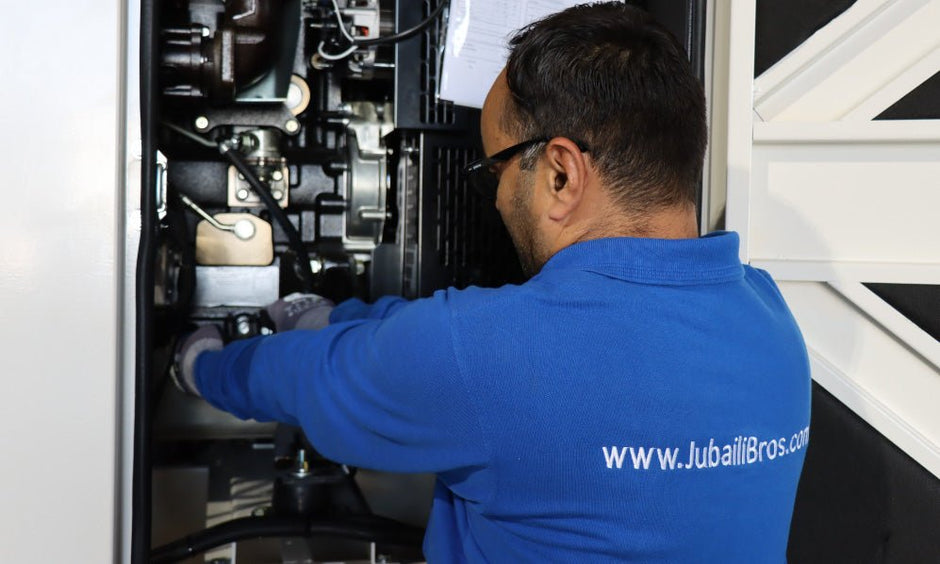

How Jubaili Bros Delivers Compliant Solutions

- Correct engine variant selection: Our team confirms the applicable emission tier for your project location and ensures the appropriate engine suffix and after-treatment system are selected.

- Factory-installed after-treatment: Emissions kits are integrated during manufacturing—avoiding field retrofits or delayed compliance.

- Complete documentation: Emissions certificates and duty cycle logs are included with every unit to support approval processes.

- Remote monitoring: Deep Sea controllers expose urea level, DPF pressure, and regeneration status over CANbus for predictive maintenance.

Best Practices and Key Considerations

- Always confirm the emissions tier required by the authority having jurisdiction (AHJ) before ordering.

- Understand that Tier 4 Final and Stage V engines require after-treatment and have additional maintenance needs.

- Use only approved fuel and urea to avoid costly system failures.

- Ensure generator enclosures and ventilation systems are designed for the added thermal load of DPF/SCR units.

Conclusion

Emissions compliance is no longer optional in regulated markets—it is a technical, legal, and operational necessity. By understanding engine variants, after-treatment technologies, and local regulations, buyers can avoid costly surprises and ensure project success.

Jubaili Bros provides emissions-compliant diesel generator packages with factory-fitted after-treatment systems, certified documentation, and expert guidance throughout the design and permitting process.

Contact Jubaili Bros to request a compliant solution tailored to your market and project requirements.