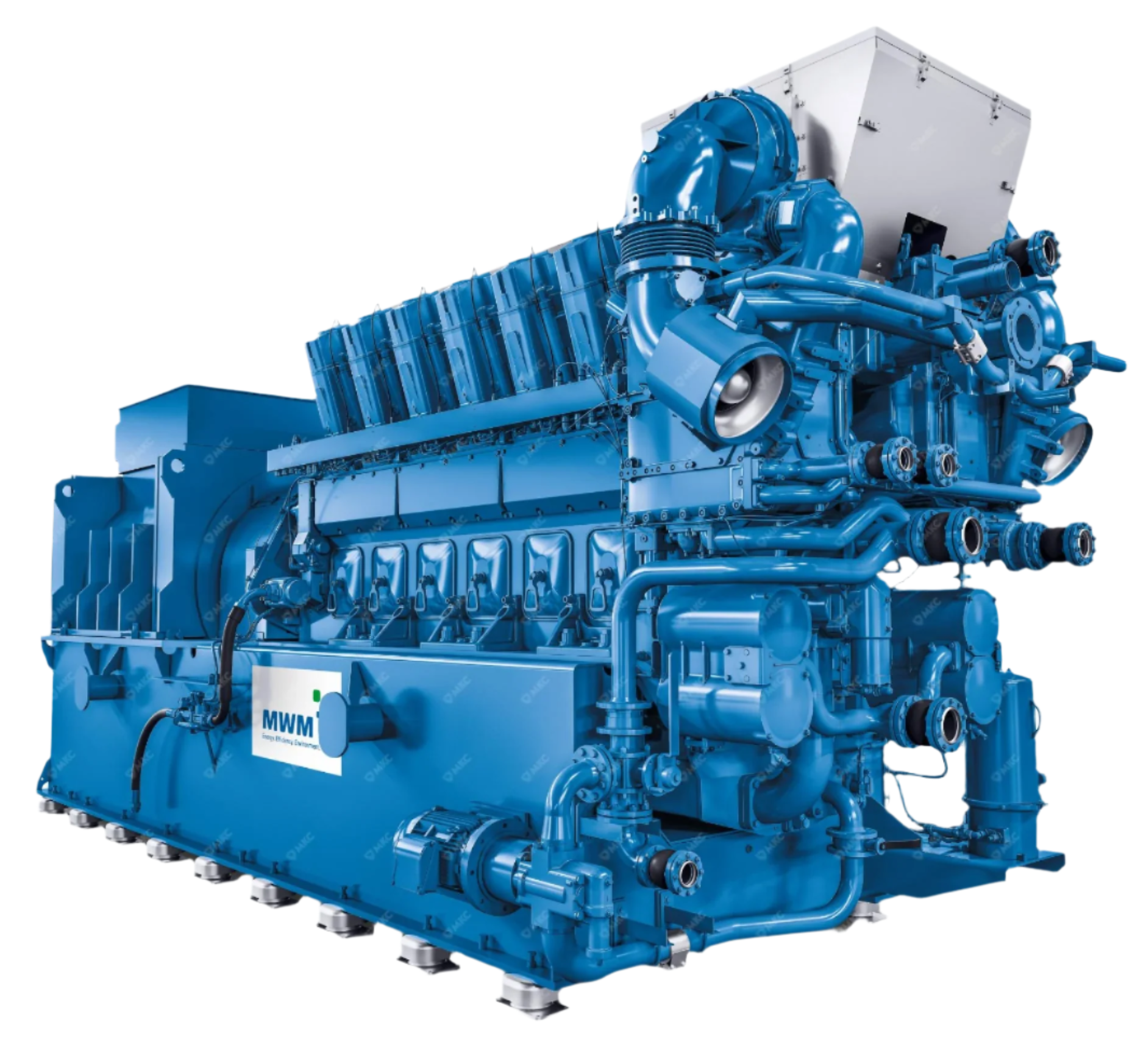

Choosing the right location for a diesel generator is just as important as selecting the correct kVA rating. A well-planned site improves performance, extends service life, reduces noise and emissions, and protects both personnel and equipment. This guide presents a structured approach to generator placement, based on Jubaili Bros’ field experience and industry best practices.

Fundamental Objectives of Site Selection

Every installation—whether at a remote telecom tower or a city-centre data centre—must achieve four key goals:

- Reliable airflow for engine combustion and cooling.

- Safe exhaust discharge away from occupied or sensitive areas.

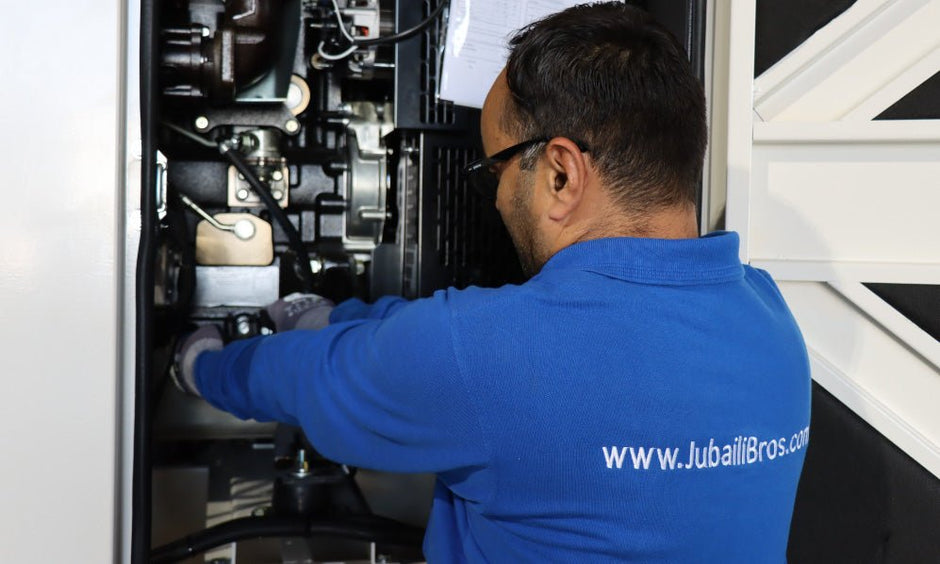

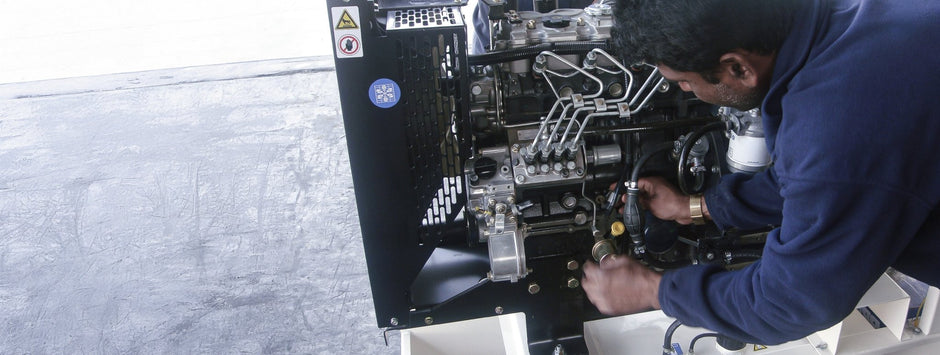

- Easy access for maintenance, refuelling, and eventual replacement.

- Compliance with structural, electrical, and environmental regulations.

Indoor Installations

When to Choose Indoor Placement

Installing the generator in a dedicated plant room is common when noise control, weather protection, or site security is critical—for example, in hospitals or high-rise buildings. Indoor rooms also shield the equipment from dust, sand, and salt spray, all of which reduce engine life in harsh Gulf environments.

Ventilation and Heat Rejection

Diesel engines reject approximately two-thirds of their fuel energy as heat—via the exhaust and cooling systems. Without proper ventilation, coolant and component temperatures rise, leading to derating or shutdown. A plant room must provide:

- Fresh-air intake: Sized to accommodate combustion air and cooling airflow. As a rule of thumb, use 0.15 m² of louvre area per 100 kW of generator power.

- Hot-air discharge: Routed through the radiator or ducted to a remote exhaust. Air must flow from engine to radiator to outside—never the reverse.

- Ventilation fan: Required if using a remote radiator, as the engine no longer pulls air across itself.

During commissioning, perform a smoke-stick test to verify that airflow enters at the alternator end and exits properly through the radiator core.

Floor Loading and Foundation

Generators impose dynamic forces. Ensure the slab supports the generator’s wet weight plus a 25% margin for vibration and fuel load. An inertia block with vibration isolators prevents structural resonance.

Fuel and Exhaust Routing

Indoor day tanks typically receive fuel from an outdoor bulk tank. Fuel lines should be routed overhead for safety, with dual-wall piping where required by code. Exhaust piping should rise at least 5° from the engine turbo outlet and terminate above the roofline with a rain cap to prevent water ingress and back-pressure.

Noise Control

Install residential silencers and acoustic louvres to reduce noise to below 70 dB(A) at 7 m. For further noise control, line the plant room with mineral-wool panels and use flexible bellows to isolate vibration from the exhaust system.

Outdoor Installations

Advantages

Outdoor generator placement—either on a skid with a weatherproof canopy or inside an ISO container—offers several benefits:

- Simplified airflow using ambient conditions.

- Shorter exhaust routing with natural discharge.

- Reduced civil works inside the building.

Canopy vs. ISO Container

Acoustic canopies (typically 72–85 dB(A)) are commonly used for sets up to ~750 kVA and are quick to install. Custom ISO containers (20 ft or 40 ft) can accommodate 1 MW+ generators and integrate bulk fuel tanks, mufflers, and switchgear in a single enclosure.

Outdoor Site Layout Checklist

- Clearances: Allow at least 1.5 m on all sides for access; provide 1 m vertical clearance for top-mounted air filters.

- Prevailing wind: Orient radiator discharge in the direction of the wind to prevent hot-air recirculation.

- Flood risk: Raise the skid base 300–600 mm above grade in coastal or flood-prone areas.

- Fuel storage: Local fire codes may require tanks to be 3 m from boundaries and enclosed within bund walls sized to 110% of tank volume.

- Security: Use fencing, lighting, and surveillance to protect against vandalism and fuel theft.

Noise and Community Impact

Outdoor generators radiate sound in all directions. Acoustic walls, fencing, or earth berms can reduce noise levels by 6–10 dB without requiring full enclosures. Always model dB(A) levels at the nearest property line—many municipalities limit nighttime noise to 55 dB(A).

Indoor vs Outdoor Comparison

| Factor | Indoor | Outdoor |

|---|---|---|

| Cooling air path | Ducted; requires fans | Direct ambient |

| Noise control | Excellent | Moderate without barrier |

| Security | High (within building) | Requires fencing |

| Installation cost | Higher civil works | Lower civil, higher canopy |

| Maintenance access | Weather-independent | May require sun or rain protection |

Environmental and Regulatory Considerations

Local codes often reference NFPA 110, ISO 8528, and municipal environmental guidelines. Consider the following:

- Ambient conditions: High temperatures, humidity, and altitude can reduce engine output by up to 15%.

- Fire safety: Ensure adequate access for fire response and use fire-rated pipe penetrations for indoor fuel lines.

- Emissions: Exhaust stack height must achieve proper dispersion—typically roof level plus 3 m minimum.

Case Study – Remote Radiator on a High-Rise

A 1250 kVA generator in a Dubai high-rise could not discharge hot air at street level. Instead, the engine’s cooling circuit was piped 35 m vertically to a remote rooftop radiator. The design respected maximum coolant head and avoided excessive boost-air pressure drops. A 35 kW fan system achieved 30 air-changes per hour in the plant room, ensuring safe operation.

Best-Practice Installation Sequence

- Construct concrete plinth and cable trenches.

- Place and align the generator (±1 mm/m).

- Connect fuel lines, exhaust, and power cables.

- Install ventilation ductwork and discharge louvres.

- Commission with a load bank at 25%, 50%, 75%, and 100% load.

Conclusion

Generator siting is a multi-factor decision that affects performance, cost, compliance, and reliability. By addressing airflow, structure, acoustics, and logistics early in the design phase, you ensure dependable power delivery that meets local codes and owner expectations.

Need expert support? Contact Jubaili Bros to review your site plans and receive tailored recommendations for indoor or outdoor generator placement.