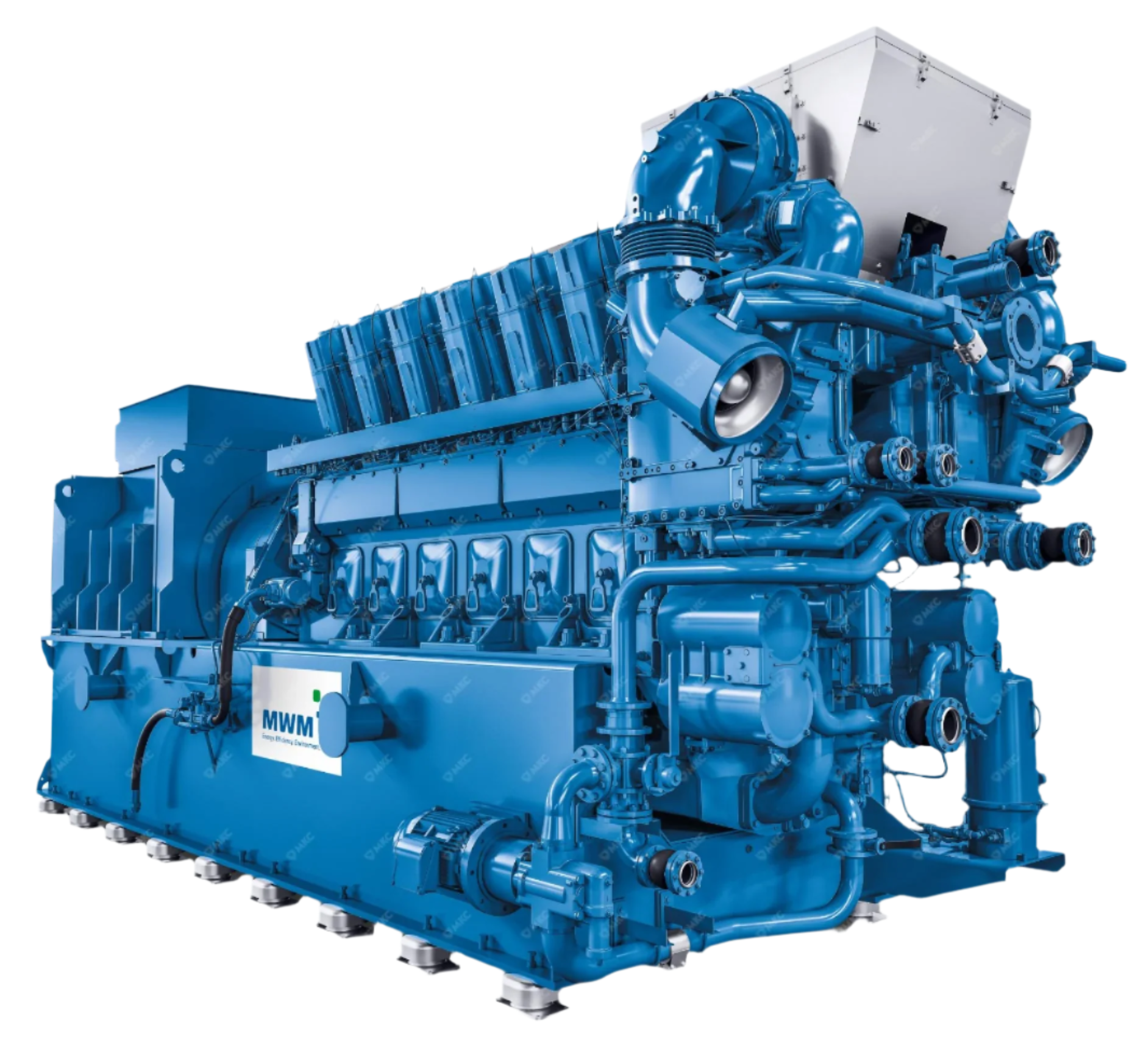

Ask a layperson what makes electricity in a diesel generator, and they will likely point to the engine. In reality, the engine provides mechanical energy. It is the alternator—a rotating electro-mechanical device comprising rotor, stator, exciter, and automatic voltage regulator (AVR)—that converts mechanical torque into the sine-wave volts and amps your facility depends on. Understanding how the alternator works, which excitation system it uses, and how it handles non-linear loads is essential to ensuring reliable generator performance.

Alternator Components at a Glance

- Rotor: The rotating magnetic field, energized by DC current and spun at 1500 rpm (50 Hz) or 1800 rpm (60 Hz).

- Stator: The stationary three-phase windings where the output voltage is induced.

- Exciter: A small AC generator on the same shaft, supplying DC to the rotor through a rotating diode bridge.

- AVR: The electronic controller that monitors output voltage and adjusts excitation in milliseconds.

As highlighted in Jubaili Bros technical training, the alternator—not the engine—ultimately determines voltage stability, short-circuit capacity, and starting kVA.

Excitation Systems Compared

Jubaili Bros alternators, primarily from Leroy-Somer, support three key excitation methods:

| Excitation System | Description | Key Benefits |

|---|---|---|

| Shunt | AVR derives power from main stator terminals | Cost-effective, minimal components |

| AREP / AREP+ | Auxiliary H1 (voltage) and H3 (current) windings supply the AVR | Supports 300% short-circuit current for 10 seconds; boosts starting kVA by up to 30% |

| PMG | Permanent magnet generator feeds AVR from a stable, independent source | Unaffected by harmonics; best for motor loads and high THD |

Both PMG and AREP systems isolate the AVR from waveform distortion, ensuring stable operation even with large motor loads or electronic harmonics.

AVR Technology and Voltage Regulation

Early analog AVRs such as the R220 achieved ±1% voltage stability. Modern digital AVRs like the D350 and D510C now offer:

- ±0.25% steady-state voltage regulation (G3 performance class)

- Negative forcing to control voltage overshoot during load rejection

- Power factor and reactive power (kVAr) control in parallel mode

- Loss-of-sensing shutdown protection

- CANbus or USB connectivity for remote monitoring and tuning

Digital AVRs enhance performance and diagnostics, especially in synchronizing or load-sharing systems.

Winding Pitch, Reactance, and Harmonic Distortion

To manage harmonic currents from UPS systems, LED lighting, and VFDs, Jubaili Bros alternators are specified with a 2/3 pitch winding. This design suppresses triplen harmonics (3rd, 6th, 9th) and limits total harmonic distortion (THD) to below 5%—even under 100% non-linear load. In cases where harmonic loads exceed 60%, the alternator should be upsized or selected with lower reactance to preserve voltage waveform quality.

Motor Starting and Short-Circuit Performance

Motors can draw 6–8 times their full-load current at startup. Alternators with PMG or AREP excitation can deliver up to 300% rated current for 10 seconds to support motor starting without significant voltage drop. In contrast, shunt-excited alternators typically limit to 180%, making them unsuitable for heavy-start loads like chillers or crushers.

Integration with Generator Control Systems

The alternator, AVR, and generator controller (such as the Deep Sea 8610) operate in a closed loop. The controller monitors voltage and frequency, commands the engine governor, and adjusts AVR setpoints via CANbus to match phase and kVAr during synchronization. Advanced AVRs like the D350 allow real-time adjustments to improve load acceptance and balance in parallel systems.

Maintenance Focus Areas

- Bearing lubrication: Re-grease every 8,000–10,000 hours or as recommended by the OEM.

- Insulation testing: Megger test annually; insulation resistance should exceed 2 MΩ at 1 kV.

- Diode bridge: Inspect using infrared thermography to detect hot spots.

- AVR firmware: Keep software updated and record parameters in the maintenance log.

- Cooling airflow: Clean air inlets, filters, and louvres to prevent overheating and varnish degradation.

Troubleshooting Quick Guide

| Issue | Likely Cause | Recommended Action |

|---|---|---|

| No voltage build-up | Loss of residual magnetism or AVR fault | Flash rotor with 12V DC; inspect AVR fuse |

| Unstable voltage under electronic load | Shunt system sensitive to harmonics | Upgrade to AREP or PMG |

| Low voltage during motor start | Undersized alternator or weak excitation | Select AREP+ or larger alternator frame |

| Repeated AVR trips | Overtemperature or unstable AVR settings | Clean ventilation path; recalibrate AVR gain |

When to Upgrade an Alternator

Consider an alternator upgrade when:

- The non-linear load exceeds 60% of generator rating

- Large motors are started from a single set

- Generators operate in parallel and show uneven reactive sharing

- Voltage stability or AVR reliability is a recurring issue

Jubaili Bros can retrofit PMG kits or upgrade AVRs to the D350 on TAL alternators—even after installation—to improve performance.

Conclusion

The alternator is the backbone of power quality in any diesel generator system. Proper selection of excitation system, AVR, and winding configuration directly influences voltage regulation, harmonic tolerance, and load acceptance. By understanding alternator behavior and maintaining critical components, consultants and operators can ensure long-term performance and system reliability. Jubaili Bros stands ready to support these needs with expert sizing, upgrades, and field services tailored to your application.

Need help selecting or upgrading your alternator? Contact Jubaili Bros for expert support and field-proven solutions.