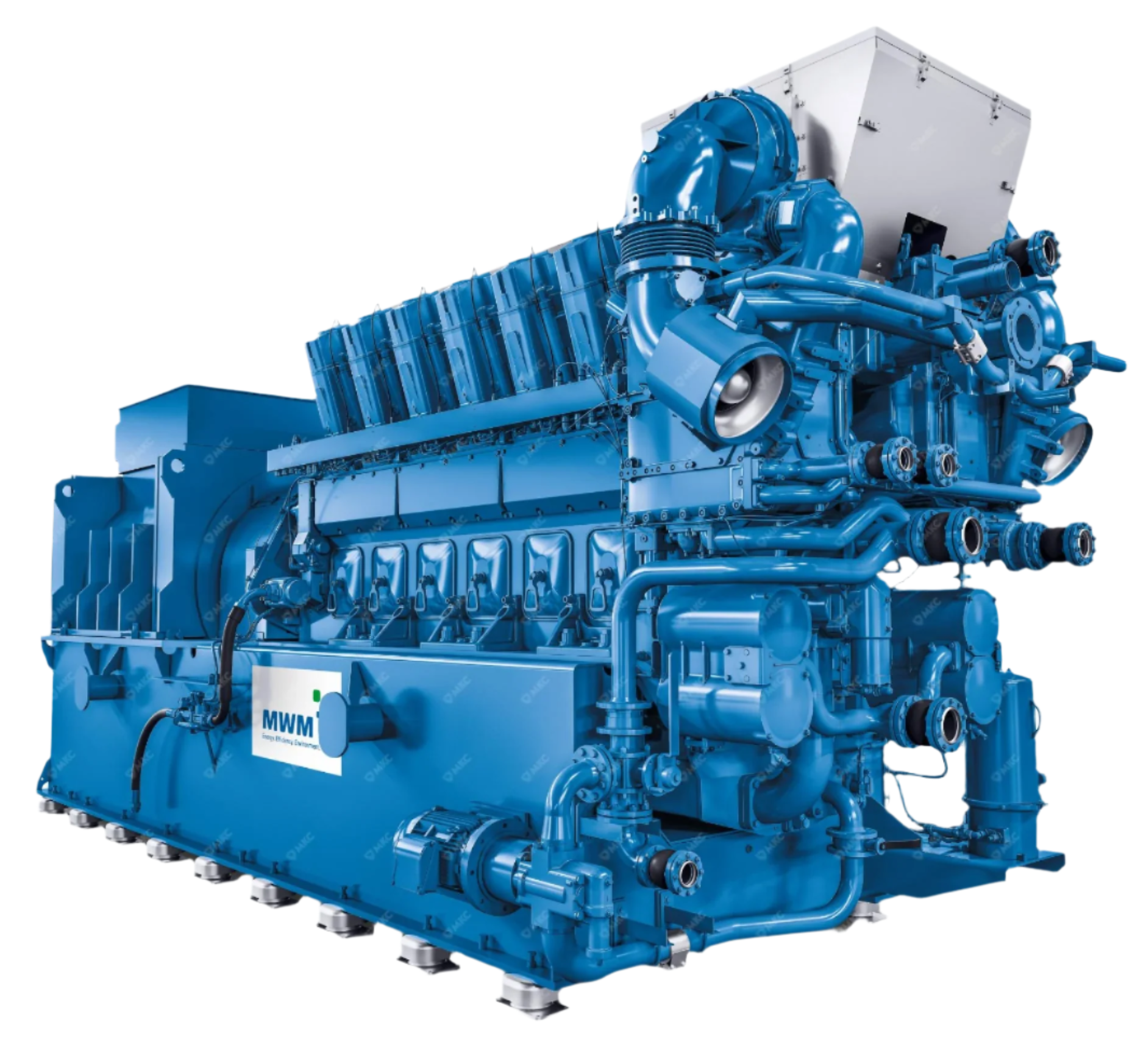

A diesel generator—whether used for standby, prime, or continuous duty—is a highly integrated machine combining mechanical, electrical, and electronic systems. Understanding its core components is essential for engineers, facility managers, and contractors when specifying options, planning service schedules, or diagnosing faults. This guide breaks down a genset into its major assemblies, explaining the function, construction, and critical considerations for each subsystem.

Diesel Engine

The engine converts diesel fuel into mechanical energy through combustion and delivers rotational torque to drive the alternator. Core elements include:

- Block and Cylinder Head: Typically cast from high-strength iron alloys like cast iron or compacted graphite iron (CGI) for structural rigidity and thermal conductivity.

- Fuel Injection System: Modern engines use high-pressure common rail or unit injectors operating up to 2000 bar for precise atomization and emissions control.

- Turbocharging and Charge-Air Cooling: Turbochargers increase air mass entering the cylinder; intercoolers reduce air temperature to improve volumetric efficiency and reduce NOx emissions.

- Cooling Circuit: Water pump, thermostat, jacket water piping, and radiator work together to maintain an optimal 80–95 °C coolant temperature. Extended service packages may include remote radiators or glycol systems (see Article 18).

- Lubrication System: Gear-driven oil pump, spin-on filters, and heat exchangers ensure continuous protection of bearings, crankshaft, and piston rings.

- Governor / ECU: Mechanical governors are used in basic sets, while electronic control units (ECUs) offer tighter frequency control (±0.25%) and diagnostics.

Power and Torque Characteristics

Power output (kW) is a function of torque and speed: P = Torque × RPM × 2π / 60. Diesel generators typically operate at 1500 RPM (50 Hz) or 1800 RPM (60 Hz). Electronic governors allow precise frequency regulation even under variable load, improving load acceptance and grid stability in synchronized applications.

Alternator (AC Generator)

Coupled directly to the engine’s flywheel, the alternator converts rotational mechanical energy into three-phase AC electrical power.

- Rotor: Generates a magnetic field via DC excitation or permanent magnets. The rotor spins within the stator to induce current.

- Stator: Stationary windings made of insulated copper conductors where voltage is induced as the rotor field cuts through the magnetic flux lines.

- Excitation System: Shunt excitation is common in basic sets. Advanced models use AREP (auxiliary winding), PMG (permanent magnet generator), or AREP+ to enhance voltage recovery and stability under transient loads (see Article 23).

- Automatic Voltage Regulator (AVR): Adjusts excitation in real time to maintain output voltage within ±1%, even during sudden load steps. Transistor-controlled AVRs (e.g., D350) are preferred for harmonics-prone or synchronized systems.

- Bearings: Sealed deep-groove ball bearings provide 8,000–10,000 hours of maintenance-free service, though high-duty applications may use double-bearing configurations.

Key Alternator Specifications

| Specification | Typical Value | Significance |

|---|---|---|

| Voltage regulation | ±1% | Maintains voltage stability under load changes |

| Short-circuit ratio (SCR) | 1.0–1.2 | Indicates motor-starting capability and fault performance |

| Winding pitch | 2⁄3 | Reduces third and fifth harmonics |

| Temperature rise | 125 °C (Class H) | Defines insulation capacity and heat tolerance |

Baseframe and Anti-Vibration System

The generator is mounted on a structural steel baseframe that serves multiple purposes: support, vibration isolation, and containment of a built-in fuel day-tank. Anti-vibration mounts—spring or rubber-in-shear—are selected based on dynamic load and site conditions (see Article 27). Proper mounting is critical to prevent vibration damage to connected loads and accessories.

Fuel Storage and Delivery

- Bulk Fuel Tank: Stores enough diesel for 8 to 24 hours at 75% load. Installation may be above ground or underground, with overfill protection and venting per local codes.

- Day Tank: Intermediate reservoir located near the generator, typically sized for 10–15 minutes of operation. Includes transfer pump, float-level sensors, and emergency shut-off valve triggered by temperature fuses or fire alarms.

- Filtration: Dual-stage systems with primary water separators and secondary 2 µm fine filters protect high-pressure fuel components from particulate and water contamination (see Article 31).

Starting System

Most diesel generators above 30 kVA use 24 V DC electric starter motors. Batteries may be AGM or flooded lead-acid, sized for multiple crank cycles even under cold-start conditions. Redundant battery banks and automatic smart chargers enhance reliability during long periods of inactivity (see Article 26).

Exhaust System

The exhaust system manages combustion gases, reduces noise, and ensures safe discharge. Key elements include:

- Flexible Bellows: Accommodate engine movement and thermal expansion.

- Silencers: Residential (critical) or hospital-grade options reduce noise to 65–70 dB(A) at 7 meters.

- After-Treatment: In low-emission zones, Diesel Particulate Filters (DPF) and SCR systems may be required to meet regulatory standards (see Article 28).

Maintaining back pressure below 7 kPa is crucial to prevent turbocharger damage and loss of power.

Cooling System

The standard configuration uses a set-mounted radiator with belt-driven fan. For indoor or high-ambient environments, remote radiators or closed-loop heat exchangers are used. Custom cooling packages may include tropical-rated radiators, glycol coolant, or cooling towers depending on the site's thermal profile (see Article 18).

Control and Protection System

- Controller: Models like Deep Sea 7320 (AMF) or 8610 (synchronizing) provide auto-start, protection functions, and user interface.

- Protection Features: Include engine shutdowns for high temperature, low oil pressure, over/under-speed, and alternator faults like over-voltage or frequency mismatch.

- Advanced Monitoring: Ethernet, Modbus, or CANbus integration allows for SCADA, remote diagnostics, and performance logging (see Article 13).

Automatic Transfer Switch (ATS)

The ATS ensures seamless transition between utility and generator power. It monitors mains voltage, starts the genset on failure, and switches load only after voltage and frequency stabilize. Break-before-make logic prevents backfeed into the grid. Some models offer bypass isolation and communication with building management systems (see Article 11).

Enclosures and Acoustic Treatment

Diesel generators can be housed in weatherproof enclosures or ISO-rated containers depending on noise and protection requirements. Options include:

- Standard Canopy (IP23): 75–80 dB(A) @7 m

- Super Silent ISO Container: Down to 60 dB(A) @7 m using baffle silencers, mineral wool, and airflow labyrinths

Acoustic and structural features are crucial for compliance in residential or hospital zones (see Article 17).

Putting It All Together

A diesel generator operates as an integrated power plant. The engine supplies torque, the alternator generates electricity, and the controller governs operation. Surrounding systems—fuel delivery, exhaust, cooling, and electrical protection—work in unison to ensure safe and reliable performance. Weakness in any subsystem reduces overall uptime and risks system failure. That's why Jubaili Bros offers full system integration and project-specific engineering support to ensure all components work harmoniously.

Conclusion

Understanding the components of a diesel generator equips professionals to make informed decisions during specification, commissioning, and maintenance. Whether upgrading an ATS, selecting an AREP alternator, or optimizing remote monitoring, each element plays a role in overall reliability. Contact Jubaili Bros for assistance in configuring or servicing your generator—our experts cover every subsystem, from engines and alternators to digital control and after-treatment.